Technology

Requirement deep hole drilling

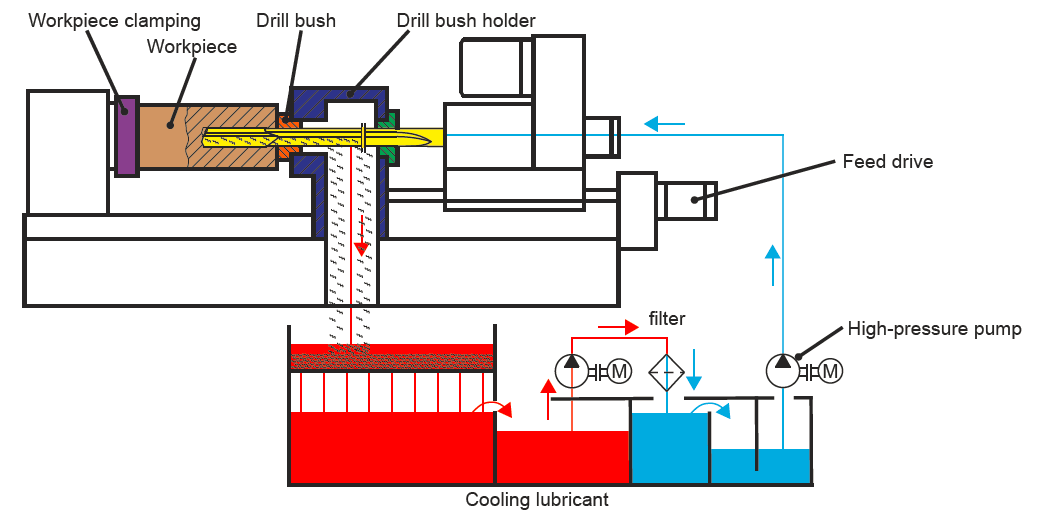

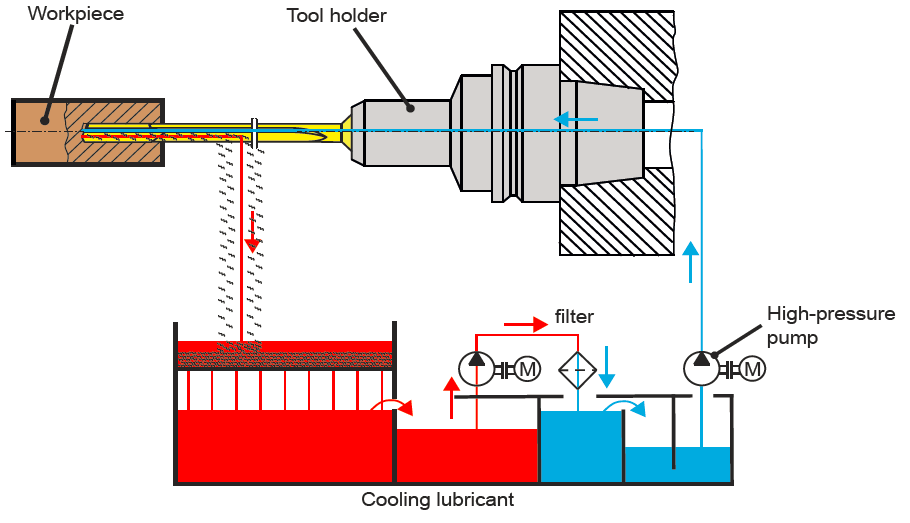

For good hole drilling results, cooling, lubrication and high-pressure coolant systems are required.

Single flue gundrilling cannot only be achieved on deep drilling machines but is also very good on machining centers (drilling, turning and milling center) with:

• Deep-hole drilling oil,

• Emulsion (min. 10 - 12 % concentration, with additives),

• and under conditions, with a minimum quantity air/lubrication system.

Drill guide

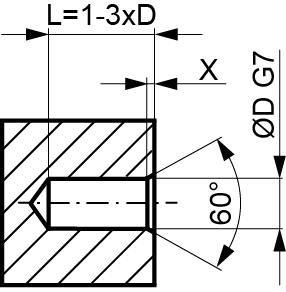

The asymmetric goemetry single-edged single flute gundrill is nit self-starting, therefore a pilot hole or drill bushing is required.

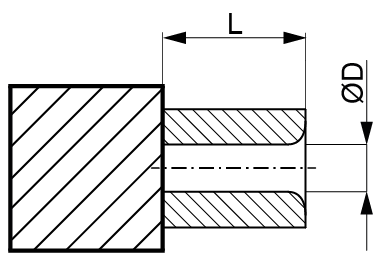

Drill bush

Recommendation: Bushes DIN 179A medium

Important: Drill bushing has a form set against the workpiece

Pilot drilling

Recommendation: pilot drill with m7 tolerance

The prevent outbreaks during retraction of single flute gundrill we recommend a chamfer (X) of 60°.

Important: Too big difference between the tool and drill bush or pilot hole can cause the following problems:

• poor hole quality

• excessive hole straightness deviation

• drill breakage

Applications

Deep drilling machine

Machining center

Procedure:

• Make a pilot hole

• Enter with stationary spindle or speed < 50 rpm

• Set coolant pressure, speed and feed

• Continuous drilling to depth without peck

• Switch off coolant supply after reaching hole depth

• Retraction with stationary or < 50 rpm

Important: Failure to comply may result in tool breakage.